Reviews

Tools

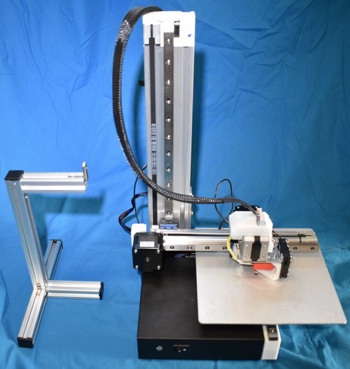

Tiertime Cetus MK3 extended 3D printer

by Blaine Singleton

Modeling Tool: Tiertime Cetus MK3 extended 3D printer

Modeling Tool: Tiertime Cetus MK3 extended 3D printer

Reviewed by: Blaine Singleton, IPMS # 50734

Scale: N/A

Company: Tiertime

Price: $499.00

Product/Stock #:

Website: Ammo by Mig

Product Web Page: View

If you have ever been interested in 3D printing, then this printer will get you started. 3D printers take a plastic filament material and melt it into an extruding nozzle, then ejected on to a moving build plate forms an object, so as the material cools it hardens. 3D printers can use several materials to melt plastic and create objects of different plastic type materials.

I have no experience with 3D printing but have always been intrigued about the idea.

I have experienced times when a special tool or part would be good to have, but there is nothing available, but now if I think about the part I can design it and at the same time learn a new skill of 3D printing. I will be honest and say the kicker for designing a part was the last time I knocked over my Tamiya cement bottle and said to myself, I wish there was something I could put the bottle in to keep me from tipping it over. Guess what my first design and project was with the 3D printer.

History

I have taken note of 3D printers and always looked to see what the latest was in printing. I have found there are a lot of web sites, Thingiverse for one, that offer peoples 3D creations that you can download direct to a printer and create that object which is nice, but I wanted to design and print my own items.

Part of my resistance to get a 3D printer was thinking it was too hard to learn to design objects for printing and I wasn’t interested in printing someone else’s stuff.

After viewing videos reviewing 3D printers, I was attracted to the Cetus MK3 extended printer. Andy’s Hobby Headquarters did a You Tube video of the printer and it was very informative. I liked the Cetus because of its simplicity, quality of materials used for construction of the printer, small footprint and the positive reviews the printer was getting.

https://www.youtube.com/watch?v=IEfPrPXcbEY

When I had the opportunity to do a review of Cetus MK3 extended printer I jumped at the chance and it has been fun learning the printer and learning how to design 3D objects.

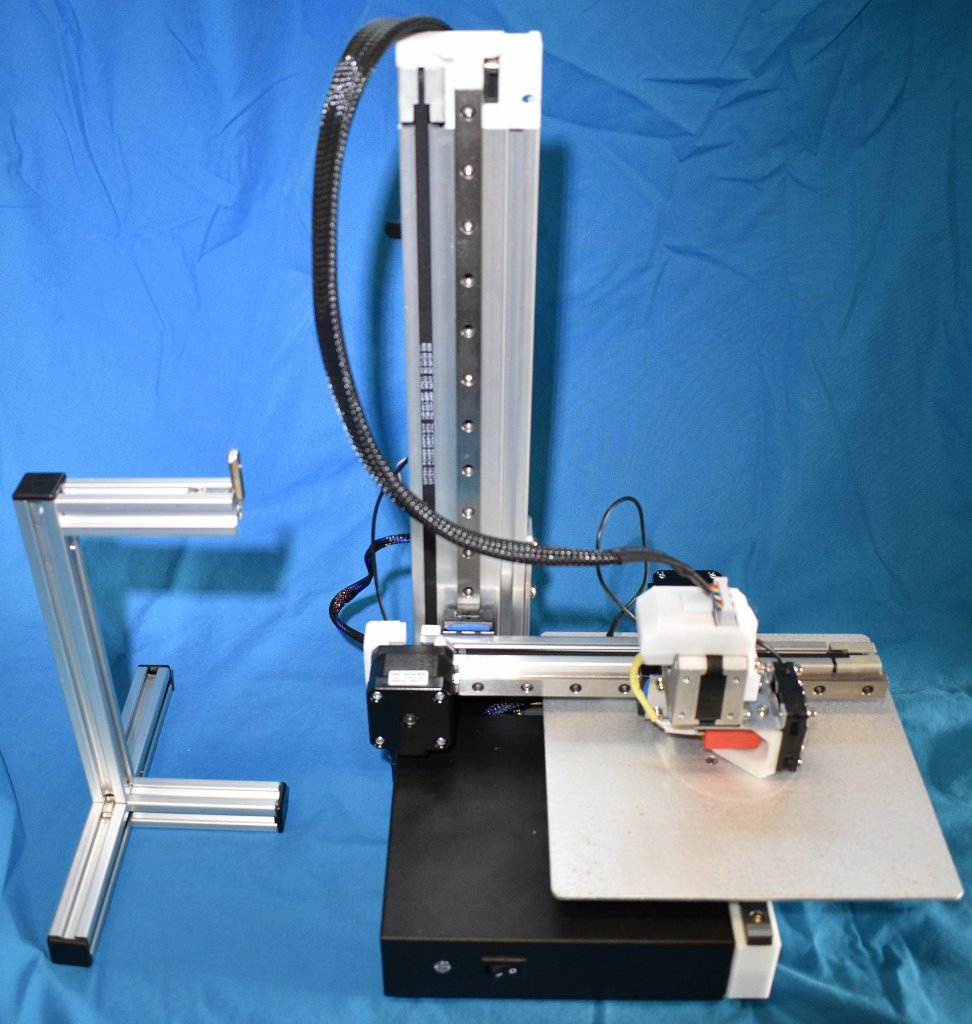

The Cetus MK3 Extended printer

One of the things you will notice about the printer right away is the simplicity of the design. It has a very small footprint (compared to other printers that look like a gantry crane system and takes up a lot of bench space). Construction of the printer is of stainless-steel linear rails for the print head and build plate to move on and have no plastic brackets holding the frame together.

The print area of the Mk3 extended printer is 180mm(W) x 180mm(D) x 280mm(H) or

7 W x 7D x 11H inches. This is a big area of print for such a small physical size 3D printer.

Cetus will be coming out with accessories such as a heated bed, good for printing ABS plastics as an example.

The reason this printer is called the extended version is that it can print a taller object than its predecessor.

In the Box When I opened the box, I was impressed with how well the printer was packaged with what I thought was a lot of care. There were no loose parts rolling around in the box to potentially damage the printer. All the printer axis motors were preassembled to their movement arms. The extruder was the only item I had to attach to a movement arm.

Printer Assembly

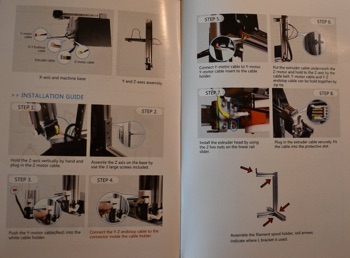

In different videos I watched about the Cetus printer, people would remark about how fast it was to set up and get ready to print. This is where the care in packaging came in, I was able to assemble the printer in 21 minutes. Tiertime when packaging the printer had subassemblies in different layers of the box which helped to speed the assembly. A quick start guide showed the different steps to assemble the printer with included photos of assembly steps, and instructions on how to download the printer operation program.

With the printer assembly parts there is also included items to make a spool holder for your included plastic PLA filament.

All tools to assemble the printer were included in the box.

Printer Construction Quality

Once the printer was assembled, the quality in manufacture and craftmanship were apparent, there were no cheap plastic parts with the potential to break, it is a sturdy quality machine.

All the X, Y and Z liner arms are made with stainless steel for accuracy and vibration elimination when making a 3D print.

Printer software

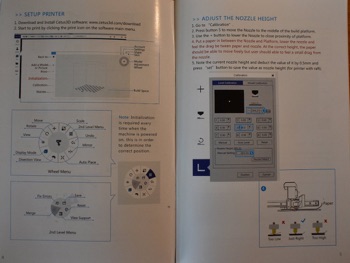

Once the printer is assembled you need to go to the Cetus site listed in the Quick Start Guide and download the software to operate the printer. Cetus askes you to establish an account so you can be notified of software upgrades.

The software also allows the printer to be remotely operated via WIFI.

Object Design program

The software that is downloaded from the Cetus site to use with the printer to design basic shapes is simple. I decided after several recommendations is to use a program called TinkerCAD to learn how to model 3D objects and design my own items. To learn the program, it takes a couple hours of watching a few how to videos on You Tube but it will get you started printing objects fast. TinkerCAD is a web-based program and when your items are designed the program allows you to download your item file to the Cetus printer.

When designing an object, I found it easier to use millimeters for measurement instead of inches. Digital calipers set to measure millimeters makes object design so much simpler.

Using the Printer

Once the printer is initialized the print head must be aligned to the build platform. A section of the software allows you to do so and may be a little intimidating, but the Quick Start Guide will show you how easy and fast it is to do. There also You Tube videos showing how to do it.

Nozzle sizes

The printer comes with three different nozzle sizes 0.2mm, 0.4mm and 0.6mm. The 0.4mm nozzle is preinstalled on the printer. Nozzle size dictates how much material (PLA) is extruded to print.

Changing the nozzle is very simple, the printer is shipped with a socket type wrench for changing the nozzles. Just make sure when you go to change a nozzle you let it cool off first. Ask me how I figured that one out.

PLA plastic print material

PLA is the material (plastic) you will use to create your 3D print. PLA is short for Polylactic Acid which essentially is a biodegradable plastic that is melted and extruded through a heated nozzle to create the 3D printed object. Guide motors move the print head on an X, Y, and Z axis.

PLA is the basic form of plastic material used in 3D printers, the Cetus MK3 can use different materials for object creation some are Nylon, PVA, PETG, Wood Fiber and ABS plastic to name a few. There is a total of 15 different materials that can be used in the printer to make objects.

PLA is most common used material for the beginner like me. The material comes on spools and you can order several different colors. The average price I have seen for PLA is around $20.00. It is all dependent on your object size and density to determine how many objects your spool of PLA will make. If you find that your object required more PLA to create than what you have on a spool, you can add to the material by inserting more material form another spool following the last of the original material entering the extruder nozzle head. Easier done than said.

Print Quality of printed objects

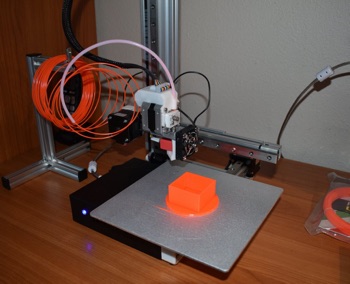

I was not sure how my first 3D printed object would turn out, but I was impressed with the print quality given my lack of 3D experience. The whole printing event went smoother than I had expected which was a very pleasant surprise.

The printer operation software is downloaded from the Cetus web page and within the program you can set parameters to change the density or the print detail of an object. If for example you choose fine detail and a dense fill of the object, it will take more time to print and use more PLA. Obviously the more you use the printer and change density of the infill of PLA for an object, you can design objects with PLA reduction requirements in mind.

First printed objects

Like I said at the beginning of the review my first object to print was a Glue Caddy that I designed to keep my Tamiya glue bottle from getting knocked over.

My second object to print was a Modelling Tool Tray. I designed the tray to hold my most used tools for modelling. Now with the toll tray if I want to work on my models other than my work bench I grab the tray and can move with no hassle rounding the tools I use most.

Summary

Reviewing this printer has been a very positive and fun event. I am now thinking of different objects that when my designing skills get better I can print. As 3D printers get better and more people use them, I think there may be a change in the modelling world as far as the ability to scratch build needed parts.

If you have ever thought about designing and printing 3D objects, then the Cetus Mk3 extended printer is a good start. My whole experience of getting the printer, assembling it and creating printed objects was way easier than I thought it was going to be. The printer can handle the requirements of the beginner or the advanced modeling engineer and has enough capability to handle printing as you get better with your designing skills.

I highly recommend this product.

Thank you to Tiertime (Cetus) and IPMS/USA for the opportunity to review the Cetus MK3 Extended 3D Printer.