Reviews

Armor

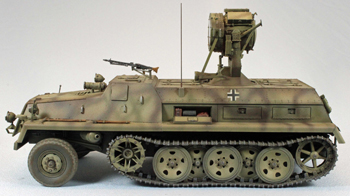

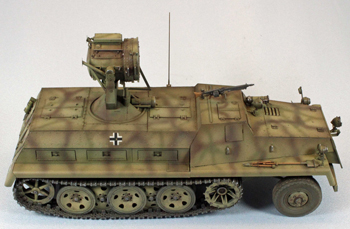

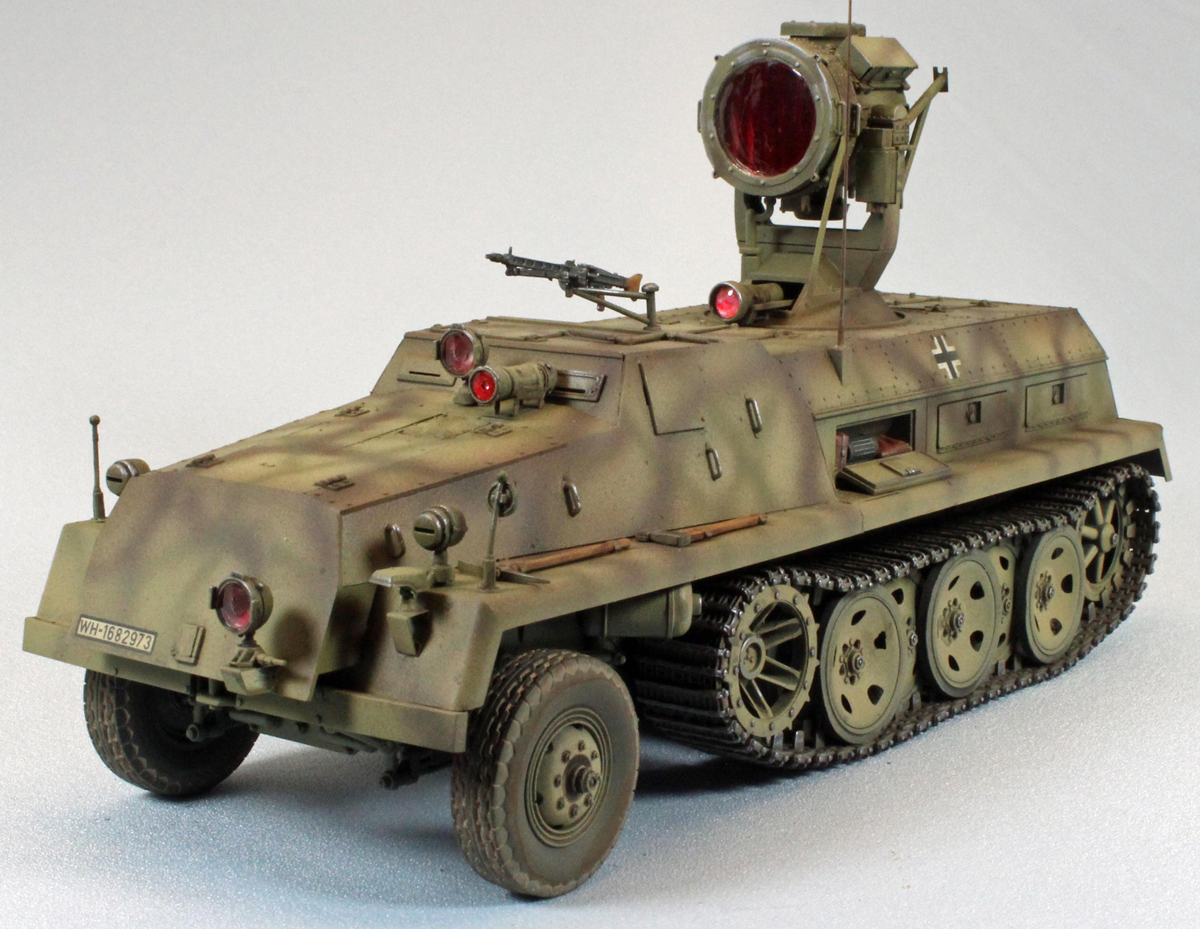

Bronco sWS 60cm Infrared Searchlight Carrier “Uhu”

by Eric Christianson

Model: sWS 60cm Infrared Searchlight Carrier “Uhu”

Model: sWS 60cm Infrared Searchlight Carrier “Uhu”

Reviewed by: Eric Christianson, IPMS # 42218

Scale: 1/35

Company: Bronco Models

Price: $58.29

Product/Stock #: CB35212

Website: Bronco Models

Product Web Page: View

Product provided by: Dragon Models USA

Summary

Newly offered in injection-molded plastic by Bronco Models out of China, is a wide-tracked sWS Utility Halftrack sporting a 60cm infrared searchlight and accompanying night-vision IR equipment.

This "new" kit is actually a reissue of the high-quality Great Wall (Lion Roar) kit from a few years back. Aside from the box art and the color of the plastic, the main difference between the two kits is that Bronco includes a complete engine assembly. At some point GW introduced these parts as an aftermarket set you had to purchase separately for their sWS kits.

Background

The subject of this kit is a fictional design. There were no plans to make an infra-red carrying sWS, not even on paper. The name "Uhu" (Eagle Owl) was not a generic name, but was applied to the Sd.Kfz. 251 20 Infrarotscheinwerfe, introduced in late 1944. The 251 mounted a 60cm infrared searchlight with a range of 1.5 km for illuminating targets at night. These specialized vehicles were tasked with guiding IR sight-equipped Panther tanks to targets that were out of range of their own smaller infrared searchlights. The technology was new and problematic, but improving. Who knows what would have come of it had the war continued.

The contents of the box include:

- 13 sprues of soft, light grey plastic

- 2 sprues of soft, light brown plastic (track links)

- 2 sprue of clear plastic (glass parts)

- 1 lower hull, packaged separately

- 1 medium sheet of decals, thin, but in perfect register

- 1 sheet of photo-etch

- 1 color print of the box art suitable for framing.

- 1 large instruction booklet, totaling 14 pages with 30 steps, printed in color.

The Instructions

As with many other Bronco kits, the instructions come in a beautifully rendered, fully illustrated, color 8.5x11 booklet. The CAD images are sharp and show the assembly from a variety of different angles to help the modeler throughout the build. That said, this is a complex kit due to the fact that is has a lot if interior detail, including a reasonably complete engine. It is relatively easy to have things go sideways unless you pay very close attention to what you are doing.

The instructions come with specific paint call-outs for Mr. Hobby, Hobby Color, Humbrol and Tamiya paints to help with painting.

Assembly sequence varies by modeler but the general flow of things go pretty much as Bronco intended. The exceptions I made are identified in the text, below. A single German tri-color scheme is included – unidentified – no actual sWS Uhu existed!

Things to consider before building:

There is a lot of photo-etch without plastic alternatives included in the box. Some of it is detail that could be left off for those modelers so inclined, but other parts are up front and center on the finished model and need to be used, such as the brackets for the IR scopes.

The kit also contains a many parts that have (male) connection tabs, but their (female) counterparts are not as much holes as they are very small indentations in the surface receiving the part - if they exist at all. As a consequence, more often than not the part doesn’t seat correctly and/or stands just proud of the surface. To resolve this you can either deepen the indentations or sand down the tabs to fit. Either way, test fit everything before applying glue.

Every single hatch, 18 of them (!) can be modeled open or closed, so some up-front work is in order to figure out what you want to show and what you want to hide. There is significant detail exposed under open hatches, including the engine and driving compartments.

It’s always important to keep in mind that Bronco kits are not for the faint of heart. That said, the parts fit, they are well-engineered, and with a little patience, will build into a great model.

Construction:

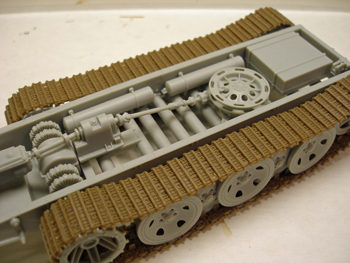

Construction begins with the lower hull and suspension. There are ten ‘tubes’ spanning the lower chassis frame, that, when inserted, tend to spread the frame slightly. This caused other parts to be loose (specifically Parts A40 in Step 7). This was no doubt self-induced, but the connection points on either end of the tubes are vague and easy to miss-align. If I build this kit again I would leave them off – they are visible on the final product, but only if you turn the model upside down.

Otherwise, everything came together well, including the slightly complicated front steering linkage (Step 4) that, once assembled, fit perfectly on the chassis.

I first encountered the sandwich-style design of the front tires with a MiniArt kit years ago, and I must say this design sets the bar for ease of assembly while providing the most authentic representation available. I simply love them. They only assemble one way, and the tread is beautifully reproduced and preserved since there is no centerline mold line to remove.

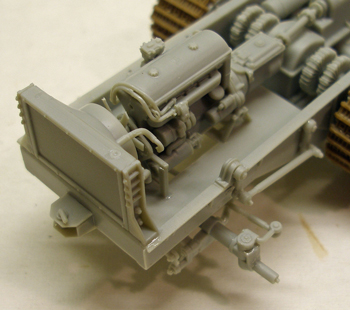

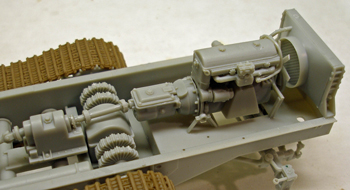

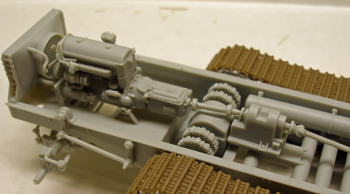

Bronco has included a complete engine and an impressive amount of detail in the lower chassis and interior, most of which can be seen only if you decide to leave some or all of the 18 hatches open. The engine and drive train is made up of no less than 61 parts that fit relatively well. The only hiccup I had was the rear trailer hitch, which when installed, interfered with the stepladder attached right next to it. In the end, I had to cut off the right third of the hitch so the ladder would line up vertically. I’m pretty sure I had things right here.

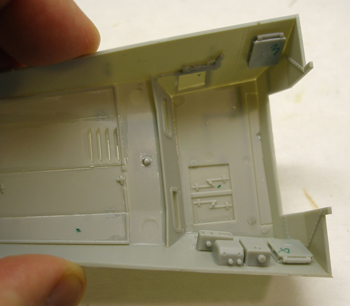

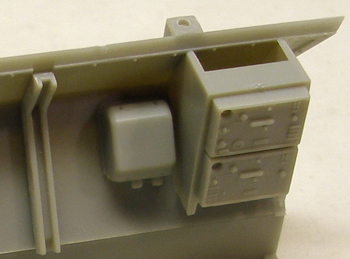

The grab handle (Part C42) in Step 12 attaches to the rear dash board, not to the console with the dials – the illustration in the instructions here is misleading. Otherwise the detail in the cab is impressive, and visible, through several hatches. I chose to close everything up so I took a few photos of the interior first.

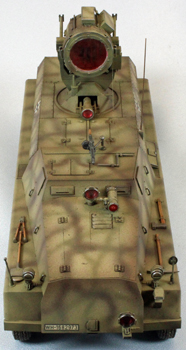

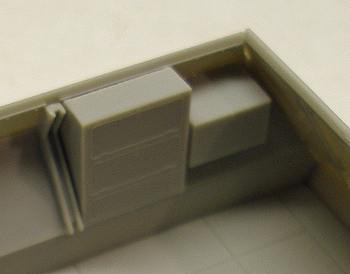

The upper hull is made up of a number of flat panels that come together along beveled edges. I used Testor’s (black bottle) liquid cement here since it has a longer drying time. The panels slide around but come together nicely in the end to produce a solid top and rear compartment. There are so many hatches and lockers that can be modeled open or closed, with exposed interior detail, that it was difficult to rationalize closing them up. I left one storage locker open on the right-hand side (couldn’t resist!), filling it with items from my spare parts box. The only criticism I have is model manufacturers’ habit of providing photoetch parts simply for the sake of photoetch. In Steps 19, 24, and 25, Bronco provides 15 perfectly good (plastic) grab handles, and then has you add six more tri-fold, (PE) versions. Annoyed, I replaced these with plastic parts from my spares box and moved on.

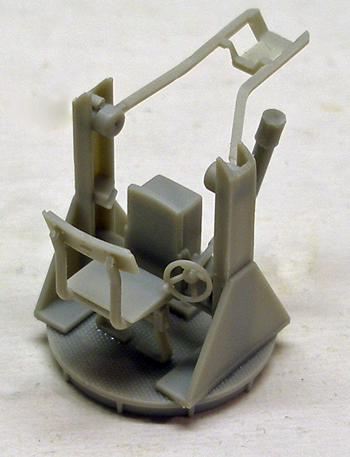

Bronco provides the option to model the main searchlight in combat mode (pointed forward) or travel mode (pointed straight up).

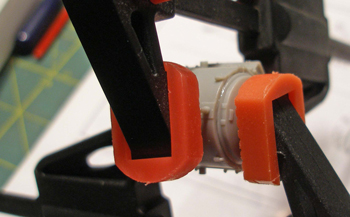

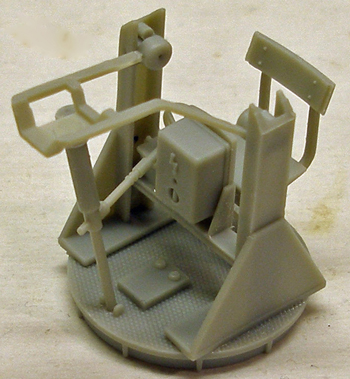

The main searchlight had a few issues but ended up coming together ok. Fully half of the detail is comprised of the gunner’s position (Step 23) and is completely hidden if you choose to close up the hull. The back cover (Part E24) is a very tight fit, requiring a clamp to keep it from spreading the two halves (Parts E53/E54) apart (see photograph). I highly recommend that you glue these three parts together before you do anything else in Steps 25-26, otherwise you run the risk of breaking off everything that you painstakingly attached along the way (like I did).

There is a tiny, molded-on hand-crank on Part E52 that wants to break off at every turn. Do yourself a favor and make note of where it is, snip it off, and re-attach it at the end of the build, before painting. The six photoetch louvers that fit inside the large searchlight are a snap to assemble if you follow this procedure:

- Paint the front side of (clear) Part F1, if desired, and let dry. I used Tamiya Clear Red.

- Glue Part F1 into the cylinder (Part H).

- Insert the six PE parts into the slots along the sides of Part H and apply glue to only the ends that are attached to the gray plastic.

As far as the other four IR lamps – assembly went fine but they all relied on photoetch parts to connect to the main hull – parts without plastic alternatives.

I attached the track early, after Step 11, instead of waiting until the end per the instructions. I wasn’t going to paint them separately, and waiting until the end risked breaking delicate parts added later in the process.

The individual track links are of two sizes; the larger part that contains the guide posts and the small part that links the larger parts together. Both come on sprues and have four attachment points each, and are not sided. Thanks to very small and easily accessible attachment points, I did not feel I had to do any clean-up whatsoever after removing them from the sprues. That said, there is a prominent ejection mark on the inside of each of the larger parts, and the small parts contain detail on only one side (the outside). Purists may want to replace them with aftermarket track, or spend a lot of time cleaning the track up before assembly – certainly more time than I have!

Bronco’s instructions say to use 112 pieces per side, which I assume to mean 56 of each kind of part to equal 112, total. Counting out the links, that leaves an extra 12 parts of each type in the box – enough for a spare track run to place somewhere. I found I had 4 big parts and 3 little parts extra, per side, even with sag, making mine 105 per side, 53 ‘large’ links and 52 ‘small’.

Assembly is tricky; the smaller segments drop into place between two of the larger segments, which would seem simple to accomplish if not for the fact that the larger parts want to move around while you are creating each run.

I solved the problem by using a scrapbooking product called Wonder Tape, which is a slightly tacky, two-sided, spongy tape that has just enough push in it to hold on to the links while you work. You can find Wonder Tape at any well-stocked craft store. I stuck the 1/8th inch-wide strip of tape on a glue-proof surface, about ¼ inch above and along a 15-inch ruler. After laying out the larger links about 1/8th of an inch apart from each other, I went back and dropped the smaller parts into place. I then added two drops of Model Master slow-drying cement (the black bottled variety) to the connection points between the links and let that sit for about 30 minutes. I then lifted up the run and carefully peeled off the Wonder Tape, and draped it on to the vehicle. One more session for the other side and I was finished. Nice.

The last two steps bring the track and the four main chunks of the superstructure down on to the chassis. This is where I had the most fit problems, and because there is so much breakable detail involved, the use of clamps is very limited. I discarded Parts D6 (no point) and had to use (Perfect Plastic) putty to fill in the minor cracks and seams created here.

The nicely fitting jack assembly ended up in the spare parts box, unfortunately – there was no room for it up next to the tools where the instructions tell you to place it once the front upper hull is in place.

Painting and Finish

Since this vehicle did not actually exist, I had some latitude on how to finish it. In the end, I went with a variation of the German tri-color scheme provided in the instructions.

(Note: I thin all Vallejo paints 50/50 with their airbrush thinner and a single drop of Liquitex Flow Aid per 10 drops of Vallejo paint. I mix the paint in a plastic disposable cup, swish that around until it is mixed, and then pour it into the color cup on my Pasche-H Single-Action airbrush, Number #3 tip, set at 20 lbs. pressure.

I started by airbrushing a dark primer/pre-shade coat of (90% Alclad Black Primer + 10% Alclad Grey Primer) to give the plastic and PE some grip for the following coats, and to fill in the recesses and create a shadow effect near the flat surface edges, adding depth for the subsequent coats to come. Once that had a chance to dry and de-gas overnight, I gave everything a base coat of three Vallejo Model Air paints, applied in succession, to achieve a highlighted German Yellow. This was comprised of 71.025 Dark Yellow, 71.028 Sand Yellow and 71.075 Sand Ivory, applied in that order. Each paint is used to lighten the color underneath, yet still allow some of what’s underneath to show through. I then applied a camouflage coat of 71.040 Burnt Umber, followed by 71.012 Dark Green.

I originally hand-painted the insides of each of the three scopes with Tamiya X-11 Chrome Silver, but I felt that it made the scopes look too much like huge headlights. So I used some artistic license and gave each light a hand-brushed coat of diluted Tamiya X-27 Clear Red before attaching the clear lenses and masking off the fronts. I used a mix of Vallejo New Wood and Vallejo Sand Ivory for the wooden portions of the pioneer tools. To achieve the wood-like effect, I let a coat of Mig Wash Brown oil paint soak on the surface of the tools overnight before rubbing off most of it using a Q-Tip. I used Uschi Chrome Pigment for steel detail here and there, including the machine gun and tools over a coat of flat black.

With painting finished, I air-brushed the surface areas that would be receiving decals with a coat of Future floor polish to give the decals a smooth surface to slide on. Once the Future was dry, I used the Red and Blue MicroSol/MicroSet products to apply the decals. The decals were very thin and fragile – both of the stencils (#9) in my sample disintegrated into a dozen pieces, rendering them unusable. Once the decals were dry, I gave the entire vehicle a good coat of Future to seal the decals and prepare the surfaces for washes and streaking.

I used AK Interactive Track Wash for the track and Dark Wash diluted with Mona Lisa White Spirit for an overall wash. I hand-painted the two front tires using Model Master US Army Helo Drab enamel.

I airbrushed Vallejo Light Brown along the bottom of the vehicle to simulate road dust, and shot a little Vallejo Matt Varnish on any remaining shiny spots. Finally, I added a slurry of Mig European Dust pigment and Mona Lisa to the front wheel tread, brushing off most of it off after it dried. I attached the wheels, a fire extinguisher to the rear, and an antenna from my spares box. Off to the photo-booth for this tough guy!

Conclusion

As I said before, this kit is not for the faint of heart. You have to know what you’re doing, you have to have a lot of patience, and you need to know how to slow down.

Sometimes there are no easily-defined connection points between parts, or they are absent altogether. I think this is a result of Bronco prioritizing accuracy over build-ability, which is fine, but anyone planning to build this kit needs to understand that. Dry fitting and methodical inspection is ‘de rigueur’ for a project like this. In the end, however, extra effort brings satisfying results. The finished product is unique and I was able to experience a real sense of accomplishment with this challenging and interesting build.

I recommend this kit for experienced modelers only due to the complexity of some of the subassemblies and the challenges that some of the photoetch offers. All things considered, however, the build went relatively smoothly and the result is worth the effort. My hat is off to Bronco for providing yet another ambitious and interesting project.

I would like to thank Bronco Models for providing this kit for review, and to IPMS USA for giving me the opportunity to build it.